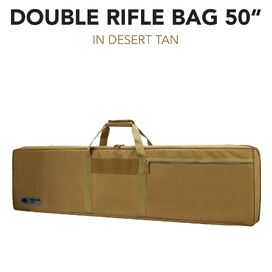

Shipping cases, custom cases, and carrying cases can be made using many different manufacturing methods, just like other items. Custom foam can be used in conjunction with shipping cases to protect valuable items. Understanding the differences between these methods will help you decide which type of custom foam you need. You can choose the gun bags & range mats for the rifle shooting accessories.

Below are the best uses and methods of manufacturing custom foam.

Custom Foam Cut to Size

The die-cutting process is used to produce large quantities of uniformly designed products (usually more than 25). The company you contract to make your products may use die-cutting if they need large quantities of a particular case to package your product for sale in retail or industrial markets.

Hand-cutting/Band Saw

The Band Saw is a great single-piece cutting method. This is a great tool for prototyping quickly with little detail and few cavities. The pattern image is usually drawn on the foam's underside and then cut using a bandsaw with a low dust foam blade. Each cavity is cut by a skilled technician. The technician starts from the outer wall of foam and then exits through the original entry point.

Water Jet Design

Water jet cutting is a very popular manufacturing technique that uses a high-pressure water jet to make precise cuts and designs. You can cut anything if you can draw it in CAD. For quantities below 25, a water jet can be very economical. It can easily cut intricate configurations, small cavities, and large numbers of cavities. Contrary to what was previously mentioned, the band saw can be tedious, time-consuming, and difficult for tiny details.