Folks working with heavy or thick materials like metals and plastics can benefit from investing in top of the line equipment. This is why it is important to investigate all possible CNC plasma cutter suppliers. Different groups around the world offer discounts and deals on a variety of items. The best model makes it easier to work with a variety of materials and be as accurate as possible while working on different projects.

By looking at all options, a company or industry professional can save money and find the best cutters around. The first thing a person should do is talk to peers and colleagues in the business. You can also get the best CNC cutting service in Sydney.

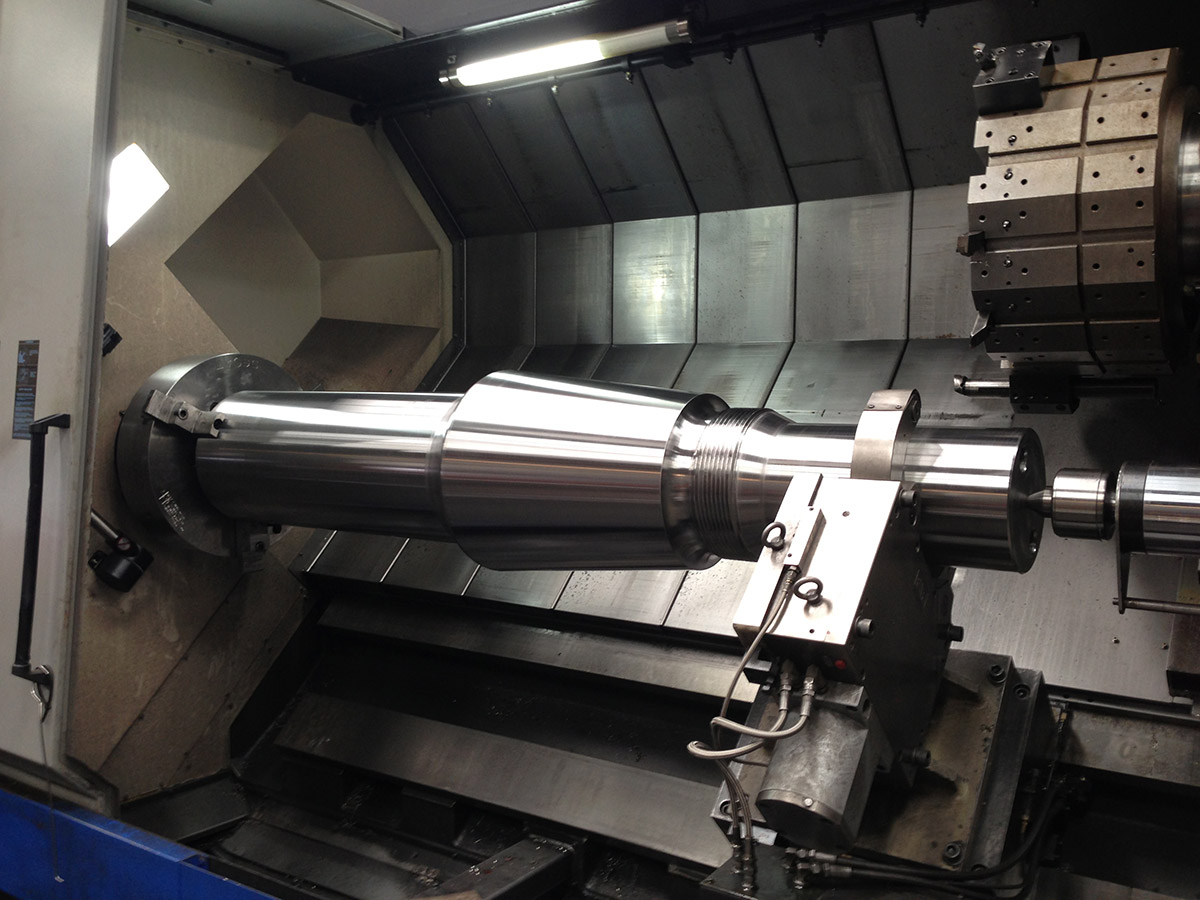

Image Source: Google

They may know about suppliers who offer the best rates and customer service, or they may have tips on companies that are selling older models. People in the industry often have contacts and types that the average person may not know about.

This is why it is important to reach out and network with other people in the same line of work. Many suppliers directly mail or contact professionals in need of plasma cutters. By agreeing to an as short- or long-term contracts, one can obtain cutters for far less than the average rates.

This is a chance to get an average idea of what such technology costs. With average prices in mind, one can spot a deal when they see it. It is also smart to look at different companies' or suppliers' websites.